Magnattack™ Global specialise in the design and manufacture of high-quality RE80™ Magnetic Separation Equipment for the food industry

Their systems are engineered to :

- Reduce metal contamination risks

- Improve product purity and food safety

- Protect brand reputation and image

- Cut equipment damage and downtime for repair / maintenance

Magnattack™ Magnetic Separators are designed to be sanitary, robust, and versatile. Powerful RE80™ Magnet Technology combined with 50+ years of hands-on, focused experience in the food industry enables the Magnattack team to provide expert advice and solutions that help you achieve an unmatched level of foreign metal contamination control.

Magnattack systems carry HACCP International and USDA dairy certifications and are designed in conformance with HACCP International 0909MAGSEP 1-2010 Food Safety Standard.

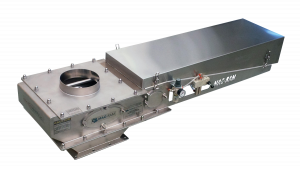

Mag-Ram Self Cleaning Separator

The Magnattack™ Automatic Self-Cleaning Mag-Ram™ Magnetic Separator has been a breakthrough in food industry magnetics by enabling rapid, hygienic, and efficient cleaning of a grate magnet…without the need to stop the process! The Mag-Ram™ can be cleaned before, during, and after production runs.

This automatic cleaning grate magnet reduces risk to final product security with the effective extraction of magnetic foreign body contamination such as tramp metal, work hardened stainless steel and stone, and fine metal fragments.

The Mag-Ram™ is suited to dry products including dairy, pharmaceuticals, infant formulas, and other sensitive applications.

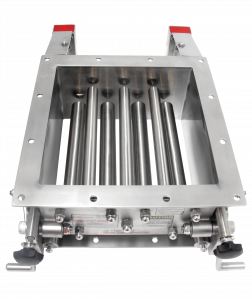

Rapidclean™ Grate Magnet

The RE80™ Rapidclean™ Grate Magnet provides superior magnetic separation in dry food product lines.

This grate-magnet-in-housing system was originally designed by the Magnattack™ R&D team to overcome disadvantages experienced by existing conventional grate magnet technology in the food industry, including stainless-steel magnet sleeves, safety issues, and cleaning difficulties. It stands out from other grate magnet designs with its sanitary dust-tight housing and a cleaning operation that is performed wholly outside of the product stream, reducing recontamination risks.

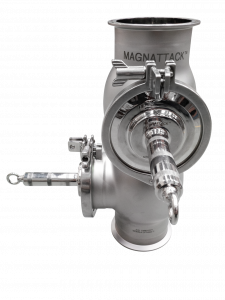

Powder Transfer Magnet

The Magnattack™ Powder Transfer Magnet is a highly sanitary magnetic separator engineered specifically for sensitive powder transfer lines such as in dairy and pharmaceutical plants.

The magnetic separator features high-intensity RE80™ +11,000 gauss Tear Drop Probe Magnets configured to remove weakly magnetic contamination and work-hardened stainless-steel fragments and stone, thus greatly increasing food safety control and product purity.

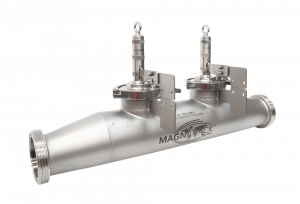

Emulsion & Slurry Pipeline Magnets

The RE80™HT Emulsion & Slurry Pipeline Separator is designed to provide hydrodynamic and hygienic metal fragment control in viscus slurries and liquid food products.

The Emulsion & Slurry Pipeline Separator features powerful, high-intensity +11,000 Gauss Tear Drop Probe Magnets. These patented Probe Magnets intercept the flow of product and extract metal fragments including work hardened stainless steel and stone particles.

Published March 4th, 2020