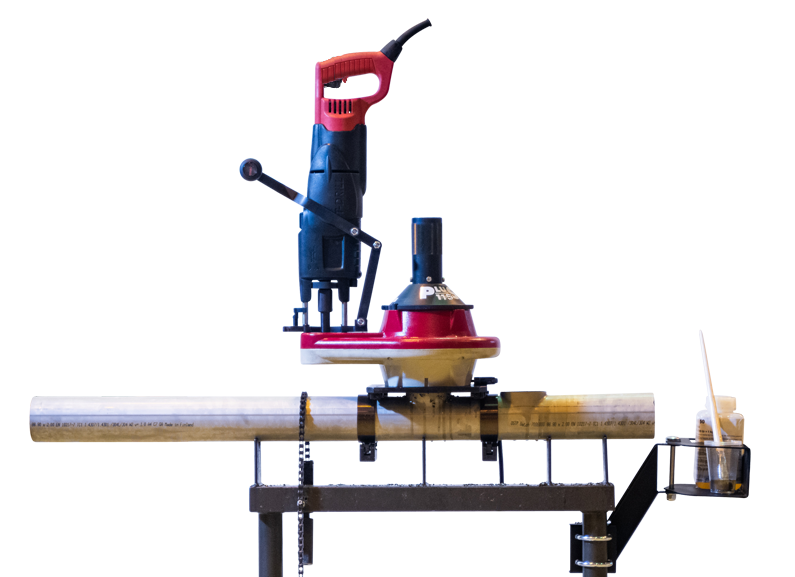

Collar sizes: 48,3–114,3 mm | 2”–4” O.D

Run tube sizes: 60,3–219,1 mm | 2 ½”–8” (When working with bigger sizes, please contact NDA)

Pipe material: Stainless steel, Steel

Machine type: Portable tools

Process: Collaring

The PLUS 115 SS Collaring System is an effortless, capacity expanding attachment for the heavy duty T-65 SS Portable Collaring Machine. It forms 48,3–114,3 mm (2″–4″ O.D.) outlets for butt welded joints on stainless steel pipes in just a few minutes.

By eliminating two welded joints, the system minimizes costs and increases profit while offering improved quality, comparable to mechanically formed tee joints. If tube polishing is required at the welding points, the PLUS 115 SS reduces this process by 60% as well. The branch pipe can be connected to a formed outlet either by orbital welding or by manual welding.

The ergonomically designed system minimizes the operator workload and is effortless to use, as it has two handles; the upper one for drilling through the pipe and the other is for elliptical movement. The powerful PLUS-115 SS is an optimal solution for the process piping industry and suits well for both construction and renovation projects, as well as the demanding field conditions in maintenance and repair work.

Key Features

- Fully adjustable for optimal elliptical shape of the pilot hole

- Easy and effortless to operate

- Simple collar height adjustment

- Ergonomic design for minimized operator workload

- Heavy duty T-DRILL collaring heads with stepless adjustment ensures precise collar sizes 48,3–114,3 mm (2”–4” O.D.)

Click Here for video and information

NDA Equipment is excited to announce its agency agreement for FitKits and Galaxis. With the technology from these companies we are able to provide a full “lights out” logistics and storage solution including both the hardware and the Warehouse Management System (WMS). The WMS is fully compatible with all ERP Solutions.

Click here to see example of WMS video

NDA Equipment are proud to be features in The Pursuit of Hoppiness May 2020 magazine !

We can provide our customer a complete brewing system!

NDA Equipment can design, construct and install the brewing system to suit almost any establishment and location.

If you are looking for Brewhouse, Filling , Packing & Fermenters please do contact us and we can designed specifically to meet your predetermined brewing equipment .

“Brew a better beer and all the world will beat a pathway to your bar”

Please contact us equipment@nda.co.nz if you would like some further information.

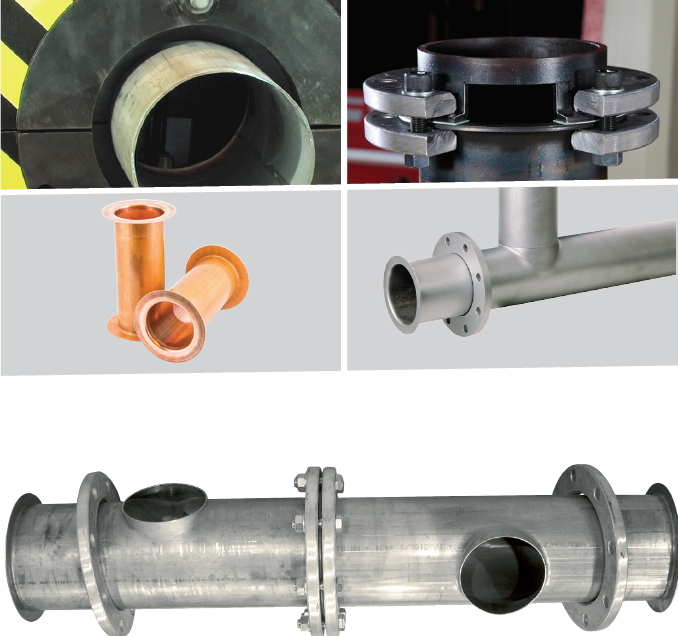

Their systems are engineered to :

- Reduce metal contamination risks

- Improve product purity and food safety

- Protect brand reputation and image

- Cut equipment damage and downtime for repair / maintenance

Magnattack™ Magnetic Separators are designed to be sanitary, robust, and versatile. Powerful RE80™ Magnet Technology combined with 50+ years of hands-on, focused experience in the food industry enables the Magnattack team to provide expert advice and solutions that help you achieve an unmatched level of foreign metal contamination control.

Magnattack systems carry HACCP International and USDA dairy certifications and are designed in conformance with HACCP International 0909MAGSEP 1-2010 Food Safety Standard.

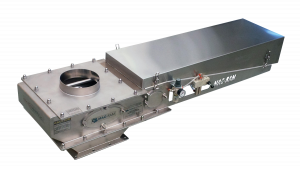

Mag-Ram Self Cleaning Separator

The Magnattack™ Automatic Self-Cleaning Mag-Ram™ Magnetic Separator has been a breakthrough in food industry magnetics by enabling rapid, hygienic, and efficient cleaning of a grate magnet…without the need to stop the process! The Mag-Ram™ can be cleaned before, during, and after production runs.

This automatic cleaning grate magnet reduces risk to final product security with the effective extraction of magnetic foreign body contamination such as tramp metal, work hardened stainless steel and stone, and fine metal fragments.

The Mag-Ram™ is suited to dry products including dairy, pharmaceuticals, infant formulas, and other sensitive applications.

Rapidclean™ Grate Magnet

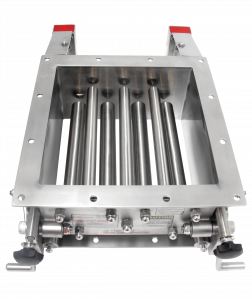

The RE80™ Rapidclean™ Grate Magnet provides superior magnetic separation in dry food product lines.

This grate-magnet-in-housing system was originally designed by the Magnattack™ R&D team to overcome disadvantages experienced by existing conventional grate magnet technology in the food industry, including stainless-steel magnet sleeves, safety issues, and cleaning difficulties. It stands out from other grate magnet designs with its sanitary dust-tight housing and a cleaning operation that is performed wholly outside of the product stream, reducing recontamination risks.

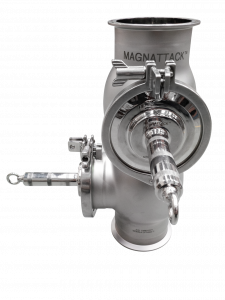

Powder Transfer Magnet

The Magnattack™ Powder Transfer Magnet is a highly sanitary magnetic separator engineered specifically for sensitive powder transfer lines such as in dairy and pharmaceutical plants.

The magnetic separator features high-intensity RE80™ +11,000 gauss Tear Drop Probe Magnets configured to remove weakly magnetic contamination and work-hardened stainless-steel fragments and stone, thus greatly increasing food safety control and product purity.

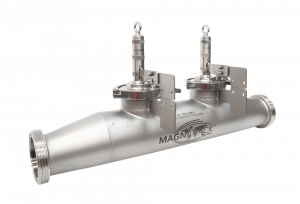

Emulsion & Slurry Pipeline Magnets

The RE80™HT Emulsion & Slurry Pipeline Separator is designed to provide hydrodynamic and hygienic metal fragment control in viscus slurries and liquid food products.

The Emulsion & Slurry Pipeline Separator features powerful, high-intensity +11,000 Gauss Tear Drop Probe Magnets. These patented Probe Magnets intercept the flow of product and extract metal fragments including work hardened stainless steel and stone particles.

The T-DRILL T-65 SS is a portable, easy-to-use collaring machine for stainless steel tubes. It is an ideal solution for making tee joints into a main run tube. While giving you comparable quality to a commercial tee fitting, the T-65 SS and T-65B SS also increase your profit by eliminating two welded joints and the fitting cost.

WHAT ARE THE P4-3 & P6-3 MODIFICATIONS?

The power sources have been modernised to integrate even more easily into companies wishing to engage in the industrial evolution towards digitalisation: industry 4.0.

As a result, the power sources of the P4-P6 range can now be integrated into a global system for exchanging information via a local network (Ethernet) or via the Internet (WIFI) and communicate with their environment and with the company (its information system, its organisation).

The recording, visualisation and analysis of welding data can be centralised, and the supervision of welding parameters of several online generators is now possible.Remote access for support, loading welding programs and data recovery results in increased productivity, quality and consumption for your applications.

The high-resolution touch panel, now independent, allows you to control, load, modify, save welding programs and connect to any power source of the same model via a quick and “hot” connection.

The new simple and intuitive user interface (IHM) includes more search criteria to suggest the welding program best suited to your application. A more visual identification then exists to distinguish the calculated programs, those of the library and yours. New fields are available to help you organize your data.

These power sources are production tools particularly suitable for all types of workshops or construction sites, even under difficult environmental conditions.

The second generation Flanging machine T-DRILL F-170 is easy to move from one place to another and fits perfectly for job site or pipe fabrication shop.

The machine is user-friendly and the working cycle is fully automatic without any tool changes. It saves costs in both labour and material in both new construction and repair work

Flanging by using the T-DRILL method takes minimum roughly a minute, while a similar process made by welding in stainless steel pipe takes up to one hour, including the preparations. Because of no welding, there’s no need for inspection of the welding seam.

Perfect for :

- Shipbuilding

- Water and wastewater applications

- Ventilation systems

- District heating and cooling piping

- Food and Brewery processing pipes

- Pulp and paper industry

- Chemical industry

- Construction and Mining Industry

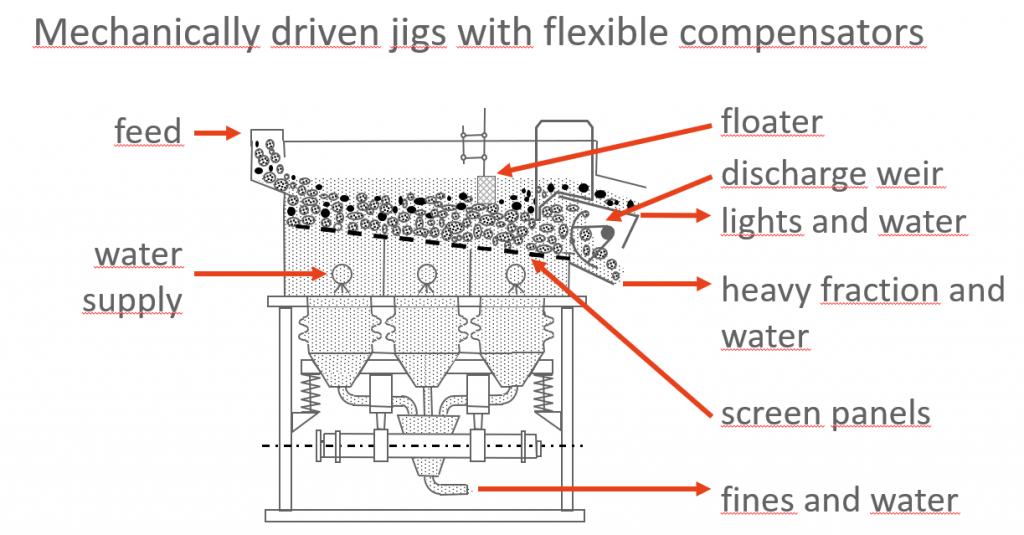

Another successful event that NDA Equipment & our partners Tema-Siebtechnik from Europe have attended.

For those who came and visited our booth, we would like to thank you for your support and possible Project opportunity that NDA Equipment & Tema-Siebtechnik can help with.

Our partnership with Tema–Siebtechnik can offer Pulsating Jigging Machines for raw material processing and recycling.

Here are some Photos of the Quarry NZ Conference & Tema Jigging Equipment

If you are interested in a project or have a question about Jigging or any other equipment we can offer, send us a message via our website and we will get back to you as soon possible.

This refurbished butter packer can wrap 250gram packs (110mm x 60mm x 30mm high) at approx. 30 per minute with parchment or aluminium foil. Has feed hopper with twin augers, a filling head, conveyor and 1.5kW motor. The Benhil 8311 Capacity is 1800 packs/hr and is in a very good condition.

The machine has had a lot of mechanical work done in 2018 replacing some parts with stainless and plastic components (especially folding blank and piston) to meet food standards. An infeed chute and safety fence has also been fitted to meet the safety standards. The fence only encloses the main drive area of the machine. The infeed chute and outfeed conveyor are outside.

Currently the machine is stored in New Zealand and comes with an operator’s manual. It has wrapped approximately 20,000 packs since the refurbishment and is now too small for production runs required by the company.

The machines dimensions are 3100mm (L) x 1100mm (W) x 2100mm (H).

The safety frame dimensions are 1300mm (L) x 1700mm (W) x 1700mm (H).

Please contact us for the price and more information.

Maus First Class Equipment & Technology enable us to help satisfy your Engineering needs.

Maus Italia is our leading supplier for tube expanders and tube rolling. They also manufacture machines for production and maintenance of heat exchangers, condensers, boilers and many more!

For more information about the Equipment / Machine that you might be interested in, please contact us here.

We have released a new Transportable Collaring Machine T-115 for productive Stainless and Carbon Steel Branching of run tubes 33,7–323,9 mm (1’’– 12’’) with branch tube diameter up to 114,3 mm (4’’).

The new T-115 machine is effortless to operate: the tools are adjustable for different branch pipe sizes, and the operation panel provides simple step-by-step instructions for starting and stopping pilot hole milling, collaring and trimming cycles.

The T-115 is only 800 mm (32’’) wide and designed for easy moving with a manual or motorized forklift. The delivery package includes also a convenient Tool Table with tool holders for easier machine usage and tool service. It is an ideal solution for both factory and on-site use for various industries, such as:

- Stainless Steel Enterprises (e.g. pumps, valves, Food & Dairy, Water Treatment, Pharmaceutical & Chemical industries)

- HVAC (e.g. heat exchangers, air pumps, radiators)

- Shipbuilding (e.g. air handling, clean & waste water, ballast (weight) water, engine tubes)

- Automotive & Aviation

- Special Applications

Key Features:

- Adjustable tools for different branch pipe sizes

- Precise collar quality

- Easy step-by-step instructions

- For both factory and on-site use

- Only 800 mm wide

- Easy to move by manual or motorized forklift

More information:

For further information about the machine, please contact us here.

Watch the video of the machine here.

NDA Equipment and Siebtechnik-Tema are attending the Quarry NZ Conference at Invercargill on the 17th – 19th of July 2019!

NDA Equipment is an agent for several international ranges of process and packing equipment plus providing engineering equipment including tube cutting and weld preparation. We cover a range of products including Sieving and Sampling equipment along with Centrifugal Separation.

Siebtechnik-Tema is part of globally operation group of companies with around 3000 employees in more than 50 companies and their expert is in the field of solid-liquid separation and the processing of bulk materials.

Visit our booth and meet up with our Equipment Experts to talk about your potential Project and Equipment!